Build a Vertical Axis Wind Turbine using the Lenz2 design

Wind turbines are usually classified as HAWTs (Horizontal Axis Wind Turbines) and VAWTs (Vertical Axis Wind Turbines). Everyone is familiar with the HAWT. Those are the windmills you see on windfarms with propeller blades turning in the wind. The VAWT looks like a merry-go-round. The HAWT is more efficient than the VAWT but it typically must be mounted on a tower and it takes a higher wind to start turning. The fact that they must be mounted high on a tower is often the cause of the NIMBY (not in my backyard) reaction that they receive. Also, because they must be mounted on a tower, additional cost and effort is needed to erect and maintain them. The VAWT, on the other hand, can be mounted low to the ground because they can start up at a lower wind speed. Also, unlike HAWTs, they do not have to adjust to the direction of the wind.

An anenometer is one example of a VAWT. The cups catch the wind and are dragged around. When the convex side comes around into the wind, the wind slows it down but not as much as it pushes on the concave side. This is why the VAWT is less efficient than a HAWT. This design is usually referred to a Savonius turbine. The Savonius VAWT is often made of barrels or coffee cans cut vertically with the halves facing each other side-by-side.

The Lenz2 turbine was designed by Ed Lenz of windstuffnow.com. It's improvement over the Savonius is that the Lenz2 uses something closer to aircraft wings instead of cups. Here is the turbine that we are going to build:

This turbine consists of three wings mounted to a vertical axis. The central axis for the turbine is an allthread bar a half inch in diameter and 24 inches long. The whole turbine is mounted on a DC motor that serves as a not very effective generator. We will only concern ourselves here with the turbine itself and not the generator.

Constructing the end pieces and ribs

First, we will build three wings. A wing consists of two teardrop-shaped end pieces connected by three ribs. The curved end of the wing and one of the flat sides are covered by aluminum flashing.

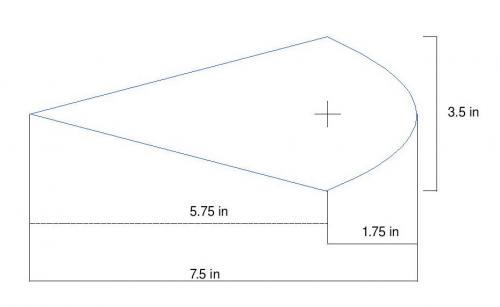

To build an end piece use the following diagram as a guide:

I would recommend that you make a carboard template and use the template to draw six end pieces on a sheet of half-inch plywood. Use a jigsaw to cut them out. You can draw the template using the following steps:

- Cut a rectangle of cardboard 7.5 inches long and 3.5 inches wide.

- Draw a line down the center of the long side of the rectangle

- Draw a line across the narrow length of the rectangle 1.75 inches from one of end of the rectangle.

- Where the two lines intersect use a compass to draw a half-circle towards the short end 1.75 inches in radius. This is the cone part of the wing.

- From where the long line meets the bottom edge, draw a line to where the half-circle meets a side. Do the same thing to the other side of the circle.

- Punch a small hole all the way through the cardboard at the center of the half-circle. This will help you mark a pivot hole on the plywood.

Cut out the template and use it to draw six end pieces on the plywood. Be sure to mark the pivot hole on each end piece. Now cut out the end pieces.

Here's what the end pieces look like:

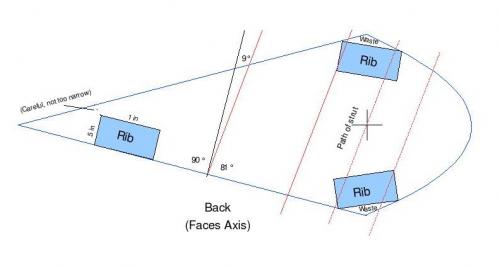

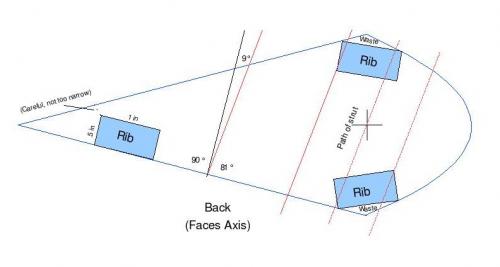

You now need to prepare each of the plywood end pieces. First, cut out a piece of cardboard .5 inch by 1 inch. This will serve as a template for marking where the ribs will dock into the end pieces. The assumption is that the ribs will be .5 x 1 inch (but 21 inches long).

Use the following diagram to understand where to mark the notches:

The two notches at the wide end of the end piece will be on the side curves. They should be all the way into the plywood so that the ribs will be flush with the side edge. The notch at the bottom is about an inch from the end but be sure to leave enough room from the other side so that the pointed end of the end piece doesn't break off.

Now we need to draw a line across each end piece that the struts connecting the end piece to the axis will line up with. The goal is to have each wing angled in towards the axis 9 degrees. From the side of the end piece where the two ribs will go, draw a line at right angles to the side. Then draw another line leaning 9 degrees away from that line towards the round end of the end piece. The above drawing illustrates this.

Drill a hole in the center of the cone where the vertical and horizontal centers meet. I used half-inch bolts to connect the struts to the end pieces. The size of the hole then was a half inch in diameter. Finally, cut out the notches with a jigsaw.

You will now have to make nine ribs 21 inches long, .5 inches deep, and 1 inch deep.

Here is a photo of the end pieces and three of the ribs:

Assembling the wings

Take two end pieces and dock three ribs into corresponding notches. Drill a pilot hole through a rib and into the side of the notch and fasten the rib to the end piece with a wood screw. Do the same at the other end. Once you have all three ribs attached, you no have the skeleton of a wing. Here are the three wings assembled:

Now cut out six strips of aluminum flashing (available in Home Depot, etc.). They should be 21 inches long. The flashing I used was six inches wide. Two of them were just the right size to cover the rounded end of the wing and the back side. I used metal screws to attach them to the end pieces and to the ribs. The back side is the side with two ribs on it.

Here are two photos of a wing that is covered and read to mount to the axis:

Mounting the wings

Create two disks of plywood 8 inches in diameter. Drill half-inch diameter hole through the center of these two disks.

The disks will be connected to the wings with struts on the top and on the bottom of the wings. I used plywood to make the bottom struts because I thought I needed them to support the weight of the wings. For the top struts I used flat steel strips with holes in them. The size of the strips should be 11 inches by 1.5 inch. There will be six struts, three for the top and three for the bottom.

Use a protractor to draw three lines from the center of the disk to the perimeter. The lines should be 120 degrees apart. Along each of these lines make a mark 1 inch from the center of the hole. Line up a strut along this line with one end starting at the mark you made. Fasten the strut to the disk with two bolts. Attach the other five struts.

Mount a wing to a pair of top and bottom struts with a half-inch nuts and bolts. Tighten the nuts enough that the wing can be rotated. Line up the top strut with the 9 degree line that you drew. Be sure that the aluminum flashing is facing in toward the axis. Now tighten down the nuts.

Here are photos showing how I mounted them:

Final Assembly

Thread a half-inch nut onto one end of the axis and position it about 2.5 inches from the end. Do the same with a nut on the other end. Slip the disks onto the axis and secure with two more nuts. The opposing nuts need to be tightened against each other so that the whole assembly will turn with the axis.

Testing the turbine

Here's my final assembly of the turbine attached to a DC motor and mounted on plywood.

You are going to have to figure out how you are going to finally erect your turbine and test it. You may already have a generator that you built or that you acquired. If not, you can test the effectiveness of the turbine by building a frame of 2x4s or PVC pipe to stand it up in the wind. The DC motor I used proved to not be very effective in generating electricity but that's the fault of the motor, not the turbine itself. A better choice might be an alternator from a car.

Here are links to two videos of the turbine turning in the wind:

http://www.datasink.com/wind/lenz2o.MOV

http://www.datasink.com/wind/lenz2q.MOV

In the second one the wind was probably blowing at 15 mph. It was moving so fast that I was afraid to try to stop it because of the sharp metal. The wire you see leading from it is being used to connect the motor to a multimeter. It barely produced 1 volt but, again, I need to find something else to actually produce electricity.

This version of the turbine is about half the size described by Ed Lenz at http://www.windstuffnow.com/main/lenz2_turbine.htm. His is 3 ft by 4 ft and is capable of producing serious electricity. The one I describe here is about 18 inches by 24 inches. If you are only trying to test the design, you could build an even smaller one of less durable materials. Be sure to keep the size of the wings proportional to the size of the turbine you choose to build.

If you are interested in what the average wind is in your area, you can visit an application that I have on my website that will let you pick a NOAA weather station near you and see a plot of wind, temperature and pressure for the past 24 hours. My application plots these data and presents them in a table. The average windspeed over the past 24 hours is calculated. If you visit your favorite location periodically, you will be able to take note of how the average changes. The link is:

http://www.datasink.com/cgi-bin/stationCodes.cgi